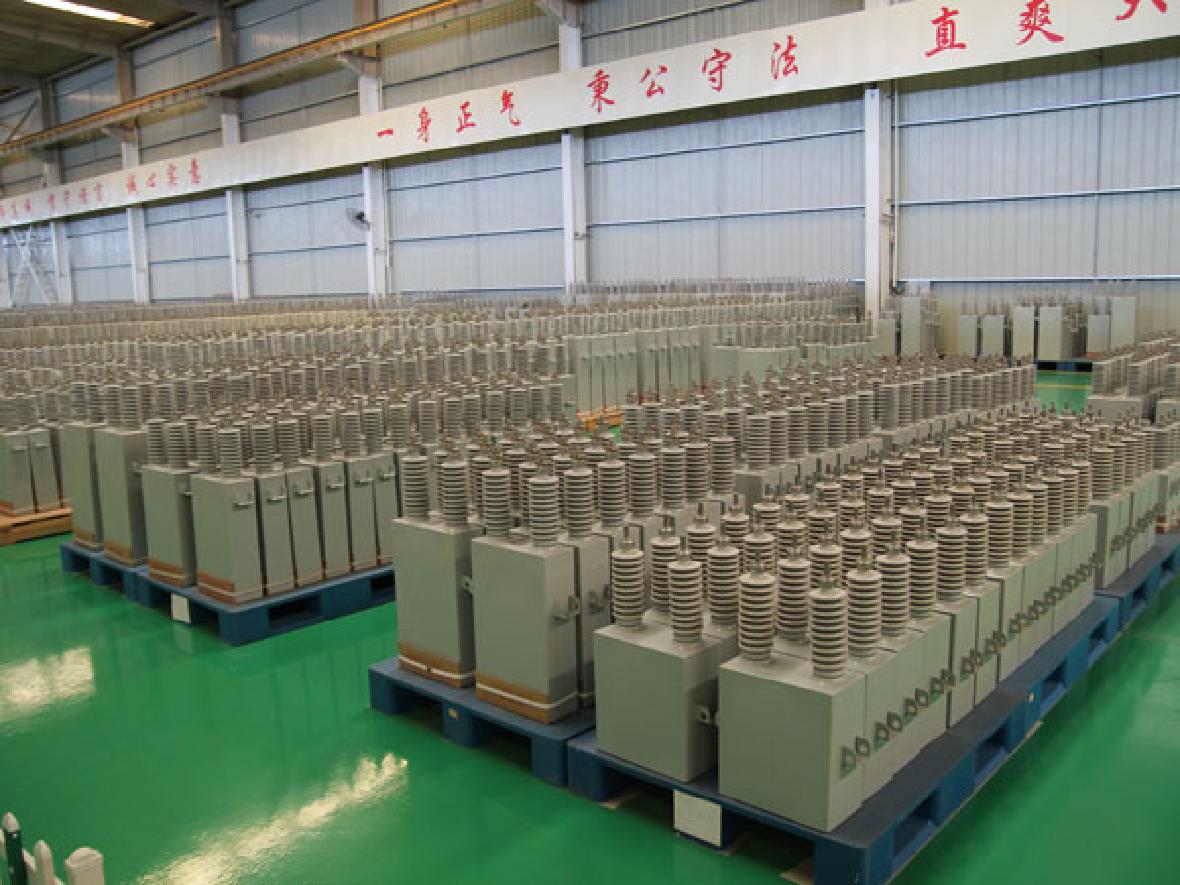

Capacitor

Product introduction:

High-voltage shunt capacitors are suitable for parallel connection in power frequency (50Hz or 60Hz) 1kV and above AC power systems to compensate inductive reactive power, improve power factor and voltage quality, reduce line losses, and give full play to the efficiency of power generation and power supply equipment.

The AC filter capacitor is suitable for connecting with other devices (such as reactors and resistors) to form an AC filter, which is connected to the power frequency (50 Hz or 60 Hz) 1kV and above AC power system to provide a low impedance channel for one or more harmonic current , thereby reducing the level of network harmonics and improving the power factor of the system.

Operating environment:

Ambient temperature range of capacitor installation and operation area: BAM capacitor: - 40 ℃ ~ + 45 ℃,

BFM capacitor: - 25 ℃ ~ + 55 ℃.

Altitude: not exceeding 1000 meters, for areas whose altitude over 1000 meters plateau products will be provided when ordering.

Product features:

² Main raw materials: high-quality double-sided roughened polypropylene film, ultra-thin (4.5μm) aluminum foil and benzyl toluene oil are selected to improve the electrical performance of the product.

² Automatic folding of aluminum foil: the head, end and edge of aluminum foil electrode of capacitor element are automatically folded to improve the electric field distribution along the edge of electrode plate and improve the partial discharge level of capacitor.

² Internal fuse: the internal fuse and element isolation structure made by patented technology completely eliminates the refusal, misoperation and group explosion of internal fuse, making the capacitor safer and more reliable.

² Discharge resistance: each series section is provided with discharge resistance, and the high-quality high-voltage glass glaze film resistance can reduce the residual voltage of the capacitor from √2Un peak voltage to below 75V within 10min after disconnecting the power supply, which ensures the safe usage of capacitors.

² Advanced core assembly assembly line: the processes from component winding, pressure selection, internal fuse assembly, core pressing, core wrapping, and core packing are all completed on the mechanized assembly line, which ensures the integrity of the core Assembly quality.

² Automatic tungsten pulse argon arc welding (TIG welding): the joint of capacitor shell, the joint between box wall and box cover, and the butt joint between the lifting lug and the shell are completed by robot workstation, so that the weld is flat, smooth, beautiful, firm and free of leakage.

² Shell shot blasting: remove the oxide layer and dirt on the stainless steel surface, and roughen the surface, which improves the adhesion strength of the paint, and effectively inspect the weld quality of the shell.

² Paint spraying robot: The imported paint spraying robot and the ultra-high-speed rotating cup type high-voltage electrostatic spray gun make the paint on the surface of the capacitor evenly and densely sprayed, and the paint surface is smooth, delicate and beautiful.

Application fields:

It is mainly used to reduce line loss and improve power factor and voltage quality of power grid.