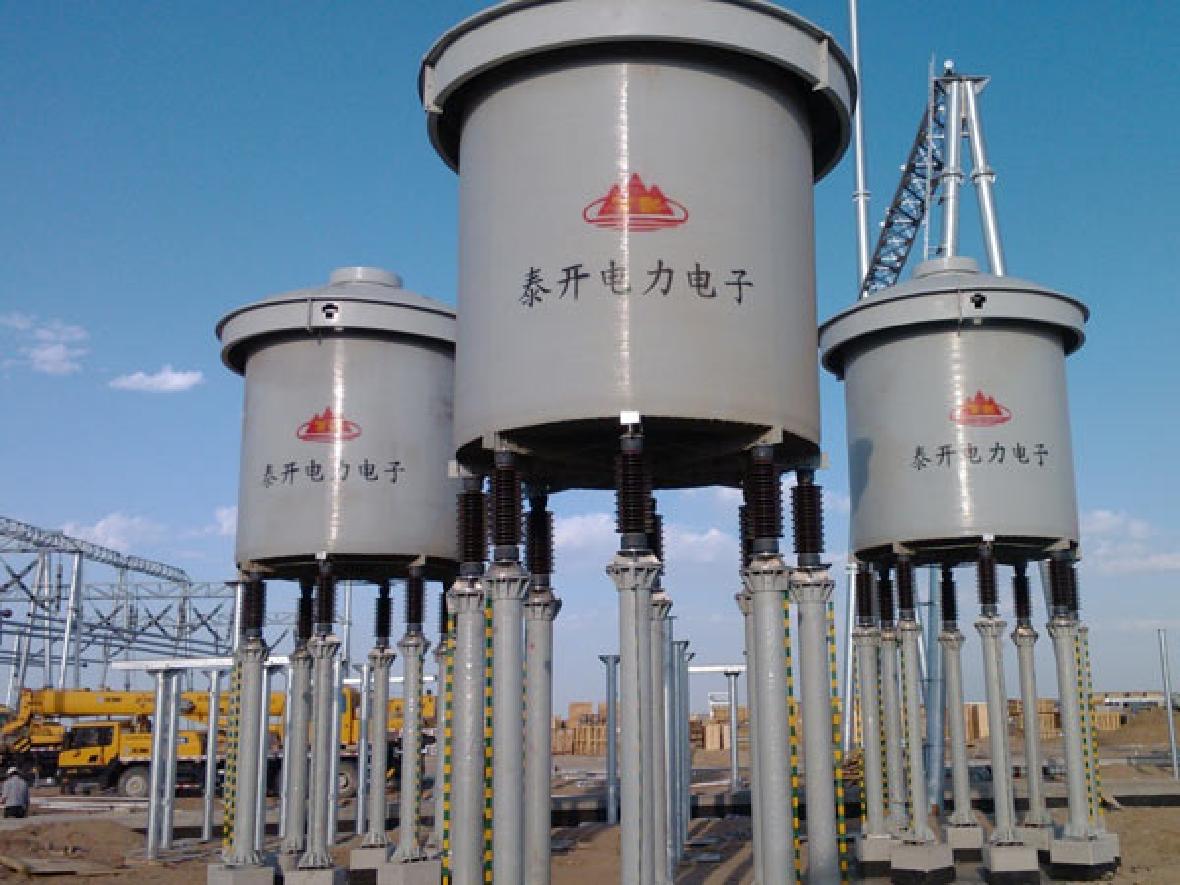

Dry magnetic-shielding shunt reactor

Product introduction

The device is connected in parallel at a winding side of transformers in substations at all levels. When the charging power of transmission and transformation lines of a certain voltage level reaches the limit of the regulations, shunt reactors shall be installed for capacitive reactive volt-ampere compensation of long-distance light load transmission lines.

Operating environment

1) Operating environment: indoor and outdoor;

2) Ambient temperature: -40℃~+45℃ (or according to user requirements);

3) Altitude: ≤1000m (or according to user requirements);

4) Installation and operation site: There should be no severe vibration or turbulence, and the site should be able to withstand earthquakes with an earthquake intensity of 8 degrees without being damaged;

5) Installation location: There should be no harmful gas, steam, conductive or explosive dust around;

6) Pay attention to ventilation and heat dissipation when using indoors;

7) Maximum wind speed: no more than 35m/s;

8) Relative humidity: the monthly average relative humidity should not exceed 90%, while the daily average relative humidity should not exceed 95%;

Note: for special requirements, please contact our company, and we will wholeheartedly meet your requirements.

Product features

1) The appearance and wire package structure of the magnetic shielding reactor are exactly the same as those of the ordinary air core reactor. It is a multi-layer parallel cylindrical structure with multiple thin wires. The difference is that the former is equipped with inner and outer shielding covers, which are stacked into a cylindrical type by high-quality high permeability silicon steel sheets, and wound with epoxy resin impregnated glass fiber bundles and solidified with the wire package as a whole, and the vibration and damp of the iron core are avoided, which not only ensures the low noise level, but also ensures that it can be installed and used outdoors.

2) The magnetic permeability of air is relatively low, while the magnetic permeability of silicon steel sheet is relatively large. The magnetic field lines of the dry-type magnetic shielding reactor are controlled to form a closed loop in the inner and outer cores, and most of the magnetic flux passes through the core, thus avoiding magnetic leakage, greatly reducing the magnetic leakage in the surrounding air, and showing obvious advantages in preventing magnetic leakage. At the same time, the safety distance during installation is reduced, the normal operation of other electronic instruments in the surrounding environment is ensured, and the environment is protected.

3) An iron core column made of silicon steel sheet with high magnetic conductivity is added to the coil, so that the magnetic permeability in the coil is greatly increased. Compared with air core reactor, under the same capacity, the diameter of coil can be greatly reduced, and the amount of conductor and power loss can also be greatly reduced. Compared with dry-type air core reactor, the volume is reduced by 20-45%, and the power loss of dry-type half core reactor is reduced by 25-40%, which conforms to the development trend of oil-free, miniaturization, energy conservation and environmental protection of national electrical products.

4) Since the magnetic flux path of the dry-type magnetic shielding reactor is composed of iron core and air, the iron core is in a non-closed state, and the magnetic density of the iron core is low. Under normal operating conditions, the iron core of the dry-type magnetic shielding reactor will not be saturated, and the reactance value is still linear.

5) The electromagnetic calculation of dry-type half core reactor adopts the calculation software jointly developed with a well-known university in China, which is extremely high in accuracy.

6) New technology is adopted to reduce the leakage current on the encapsulated surface, and the reactor surface is specially treated to enhance the antifouling insulation grade of the reactor. The iron core and each layer of coil are wrapped by epoxy glass fiber impregnated with glue, so that the coil is well protected.

7) The iron core column of the dry magnetic shielding reactor is made by integral vacuum epoxy casting, and the iron core is wrapped with a protective layer during winding. After curing, the overall structure is very strong, which reduces the vibration and noise of the iron core. At the same time, it can be directly used outdoors after being treated with special protective measures, without being restricted by environmental conditions.

8) The dry-type magnetic shielding reactor and iron core are wrapped with glass fiber impregnated with epoxy resin glue and cured into a rigid whole. At the same time, the magnetic flux is "shunted" by the inner and outer cores, the magnetic density at the reactor conductor is relatively reduced, and the overall number of turns of the reactor is relatively small. Under the same short-circuit current, the electric power received by a single conductor is reduced, which improves the anti short-circuit electric impact force.

9) In addition to the above characteristics, magnetic shielding reactor also has many advantages of dry-type air core reactor. For example:

² It is made of self extinguishing materials, no strict fire prevention measures are required;

² Small maintenance workload;

² High operation safety and reliability;

Application field

The products are widely used in power system, chemical industry, metallurgy, coal mine, electrified railway and other special occasions.